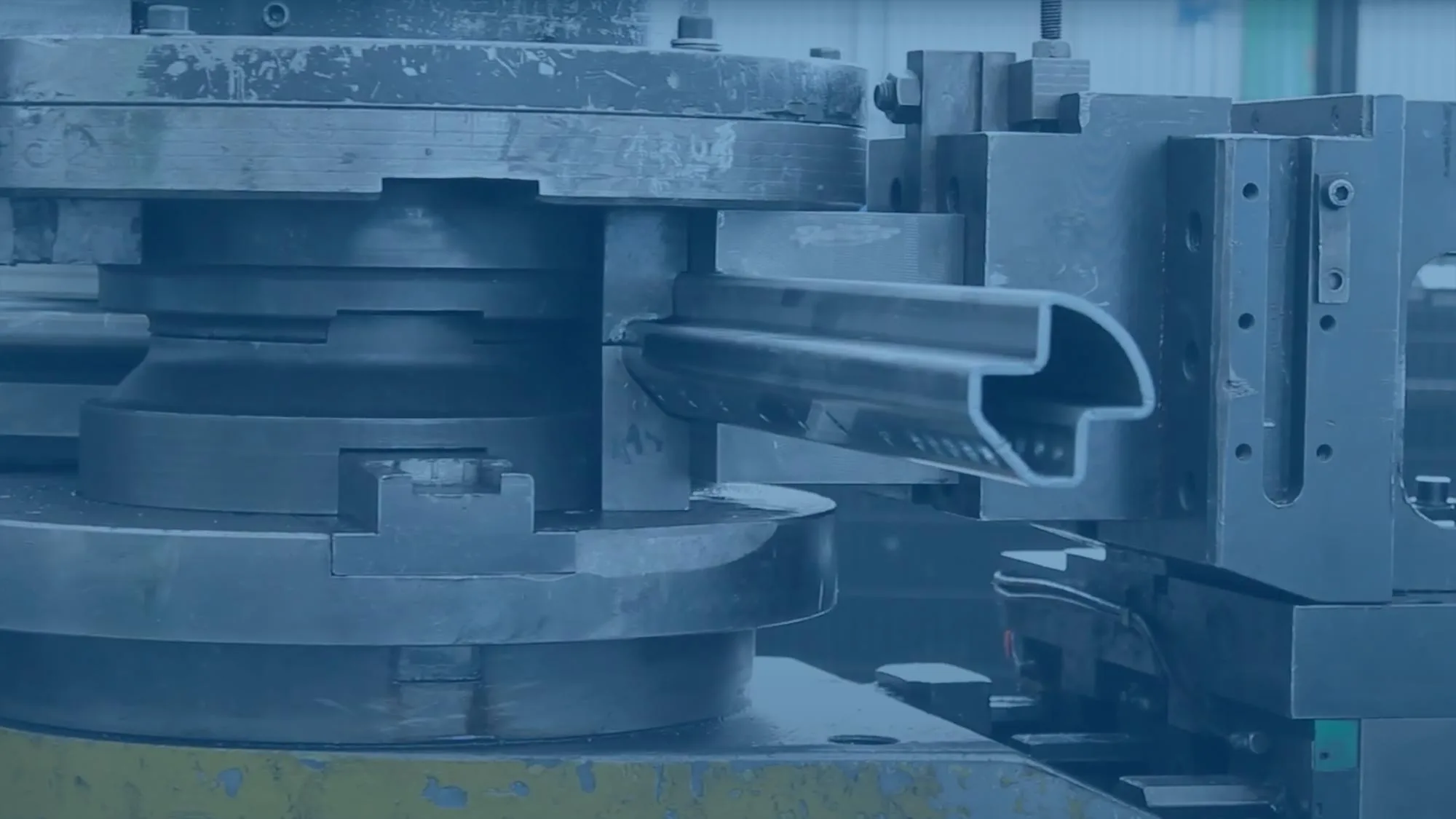

Bending aluminium and steel section bars for cabs

Bent section bars in aluminum and steel are used for the construction of the load-bearing portions of machinery with cabs.

We are specialized in bending and roll bending steel and aluminum section bars for the cabs of industrial machines like tractors, earth-moving equipment, cableways and electric cars.

Our certifications

A certified quality management system is essential to guarantee and maintain the company’s performance and value for our clients over the long term.

Tecnocurve is ISO 9001 quality certified by CSQ and since 2020 its production processes have been validated in accordance with UNI EN 1090.

Discover our 4 special section bars

When the time available is limited and there is a desire to avoid having to develop special equipment or projects that require small lots, our four special section bars for cabs are the ideal solution.

They are section bars in different metal alloys that are equipped with the rabbet for the window glass as well as the rabbet for the door of the cab. These section bars are available in our warehouse so as not to cause any delays for lead time.

Thanks to these 4 special section bars, we can complete the processing at even lower costs. In fact, the client won’t have to order special processing done ad hoc.

Industrial uses and advantages of metal section bars

Bent section bars in aluminum and steel are mainly used in the construction of closed or semi-closed cabs. The cabs serve two functions:

- They ensure the safety of the machine operator

- They enhance the comfort of the operator (the fact of being closed means that the cab can be heated and cooled)

These section bars are cold bent in accordance with the technical design specifications. They are usually used for the construction of the sides of the cab, but can also be used in other sectors (labeling machines, amusement park rides).

On these sections, the edging of the bar serves as rabbet for the door of the cab. This has two advantages:

- Reduction of time and costs of production

- Improvement of its esthetic appearance

Our bent section bars are used for the construction of cabs on the following machines:

- Tractors

- Earth-moving equipment

- Elevators

- Sweepers

- Electric cars

- Cableways

Technical characteristics of the section bars

Our special bent section bars have the following technical characteristics.

CAB1

Alloy: S275 J2

Yield stress (Reh): 335 N/mm2

Tensile strength (Rm): 455 N/mm2

Weight: 4.35 kg/m

CAB2

Alloy: S420 MC

Yield stress (Reh): 473 N/mm2

Tensile strength (Rm): 551 N/mm2

Weight: 5.56 kg/m

Alloy: S275 JR

Yield stress (Reh): 315 N/mm2

Tensile strength (Rm): 462 N/mm2

Weight: 6.75 kg/m

Alloy: S235 C

Yield stress (Reh): 285 N/mm2

Tensile strength (Rm): 430 N/mm2

Weight: 4.27 kg/m

Metal alloys

Bent section bars for cabs can be either in aluminum or in steel.

Bent steel section bars:

Bent aluminum section bars:

Bent aluminum section bars are recommended for machines that dispose of very large cabs. Aluminum is a lightweight metal and its use contributes to reduce the total weight of the machine. In some cases, the geometrical design of the cab requires the use of aluminum rather than steel.

Processing methods

The construction of section bars for cab vehicles may include, depending on the type of cabin, specific processing requiring the use of different equipment.

Bending and roll bending

The use of a bent section bar in cab construction offers a dual advantage:

- From the practical standpoint, because the section bars are already designed for the insertion of the door and window

- From the esthetic standpoint, because they make it possible to develop unconventional geometrical designs thanks to the use of bending and roll bending techniques with average fixed or variable bend radius.

With our latest generation tube bending machines, we are able to produce bent section bars with average fixed and variable bend radius.

Laser cutting and bending

The use of the laser-tube prior to bending the section bar allows us to produce holes, mitre cuts on the ends, slots, markings or micro-incisions on the section bar. Performing laser cutting procedures before bending (or roll bending) gives use two advantages:

- Greater precision in processing the section bar

- Savings of cost, as we are able to reduce:

- the time and cost of the equipment and extra processes

- the ability to perform processes that would not be possible otherwise, using our work centers

Bending and milling

Sometimes it is necessary to perform special processes on the section bar near the bent part. For these processes we use our innovative numerically controlled (CNC) work center.

They processes used include, in particular, the following:

- Milling

- Drilling

- Trimming

- Tapering