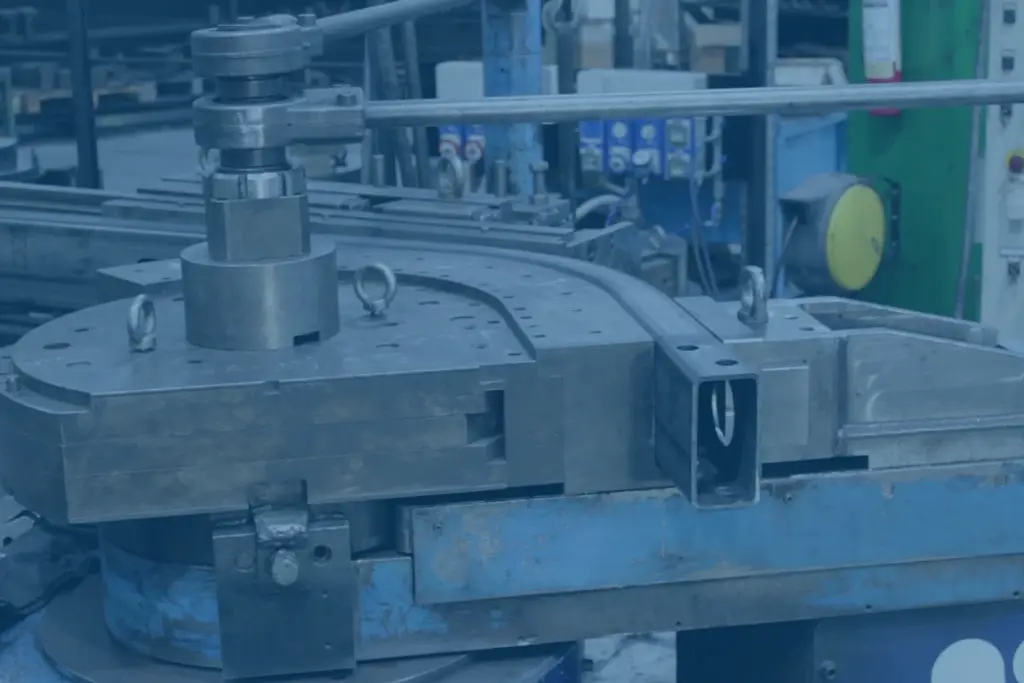

Tube bending, pipe bending, section bending

With over 30 years’ experience in bending tubes, pipes, sections and tubulars in stainless steel, aluminum and iron, we are one of the few companies in Europe capable of bending cross sections with external diameter of the tube up to 219 mm.

Types of tubes and relative cross sections

We bend rectangular, round and square tubes, and section bars of various kinds.

Round tubes

- Minimum cross section: Ø6 mm

- Maximum cross section: Ø219 mm

Square tubular elements

- Minimum cross section: 10x10 mm

- Maximum cross section: 180x180 mm

Rectangular tubular elements

- Minimum cross section: 20x10 mm

- Maximum cross section: 150x100 mm

Section bars

- Every section bar requires a special study to determine the feasibility of the bend. Regardless of the technical features, at the dimensional level, for a section bar to be in the range processable by Tecnocurve, it must have an internal diameter of 219 mm or less.

Metal alloys

Steel

The bent tube in steel is definitely the most widely used because of the suitability for cold bending of this alloy.

Since it is the product most often requested, Tecnocurve disposes of a wide range of equipment for bending square and rectangular tubular elements, round tubes and section bars

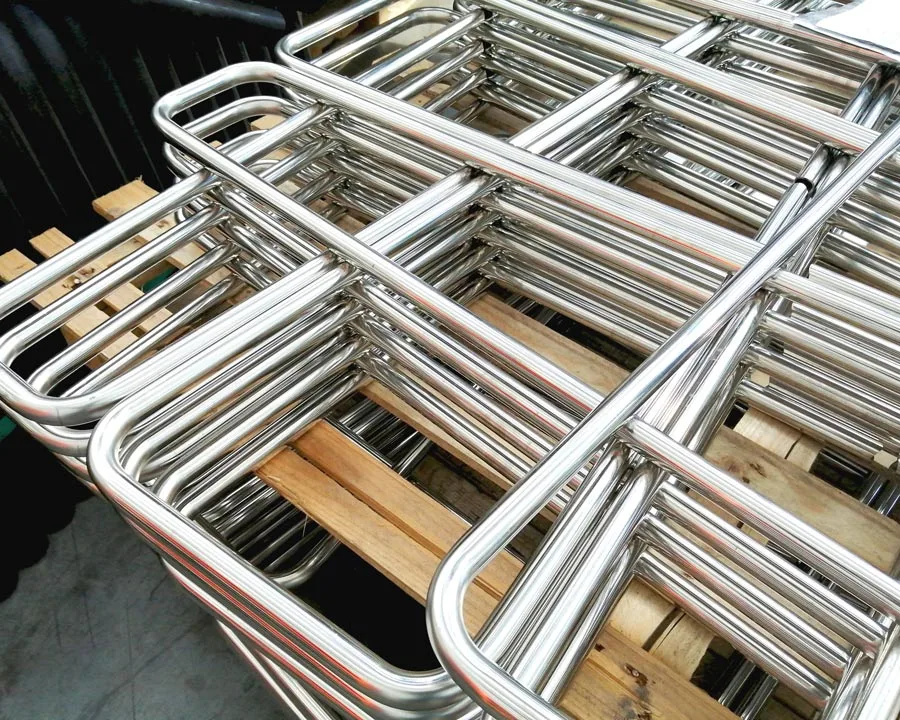

Stainless steel

Bending stainless steel tubes is simpler than bending tubes of carbon steel.

The bent stainless steel tube is chosen, however, for its resistance to corrosion or because in certain sectors the esthetic appearance of the tube is more important.

Aluminum

For best results it is essential to use CNC tube bending machines of the latest generation, operated by expert professionals.

The quality of the workmanship achieved with our FULL ELECTRIC CNC machinery ensures great accuracy and repeatability in medium and large production runs.

Tube bending methods in combination with other processes

Tube bending and roll bending

Combining tube bending and roll bending these two processes enables us to create unique geometrical shapes.

Roll bending and laser cutting

With laser cutting done immediately prior to bending, which is the cold deformation process as such, we are able to produce holes, slots, mitre cuts and many other processes, speeding the production process in its entirety.

Without laser cutting combined with bending, the time and costs would increase because the other operations would have to be done after bending, which would involve tooling more machines, which would require additional steps.

Tube bending and milling

Sectors of application: industrial uses

Our tube processing methods

Laser tube and pipe cutting

Thanks to our two modern laser tubes we are able to produce tapered, square and hexagonal holes, slots, tube-end facing, mitre cuts and marking

Tube milling

With our two work centers, here at Tecnocurve we are able to satisfy our clients even with those additional processes that require extreme precision

Lathing metal tubes

Lathing on tubes and solid round bars that can be bent or become parts of welded assemblies. Types of tubes and relative cross sections

Accessory processing

Accessory processing of tubes, section bars and tubular elements in metal Bent or roll bent metal tubes, section bars and tubular elements can also