Roll bending tubes

Types of tubes and cross sections

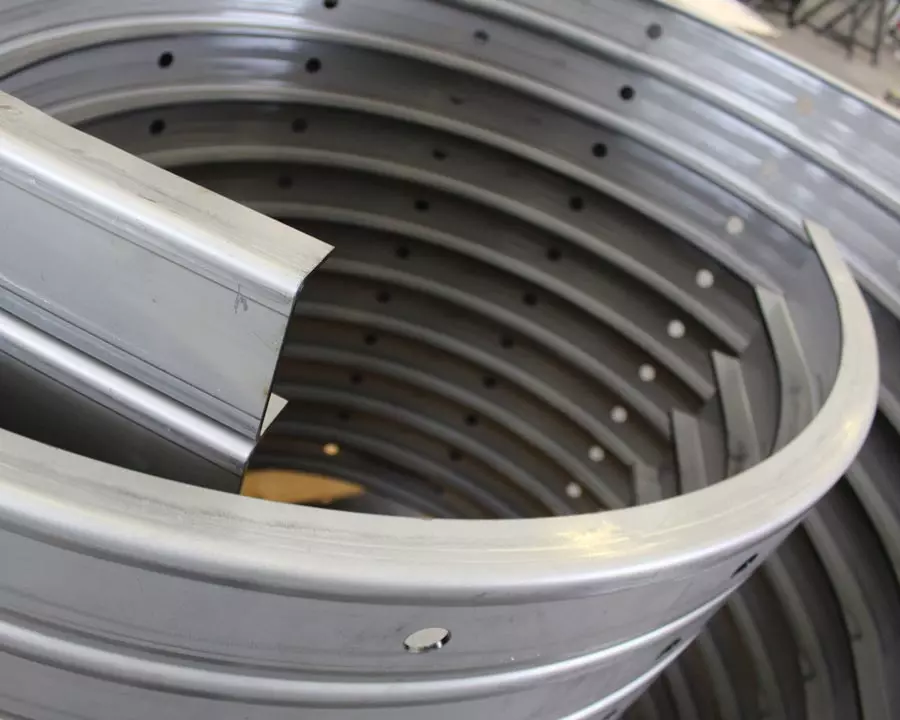

Round tubes

- Maximum cross section: Ø154 mm

- Minimum cross section: Ø10 mm

Square tubular elements

- Minimum cross section: 10x10 mm

- Maximum cross section: 120x120 mm

Rectangular tubular elements

- Minimum cross section: 20x10 mm

- Maximum cross section: 160x80 mm

Section bars

- In addition to the standard section bars available, like UNP, HeA, HeB, IPE, we also roll bend special open or closed section bars for which it is usually necessary to perform particular feasibility studies for the subsequent construction of special equipment to bend them.

Metal alloys

Steel

Stainless steel

Aluminum

Methods of roll bending and processing metal tubes

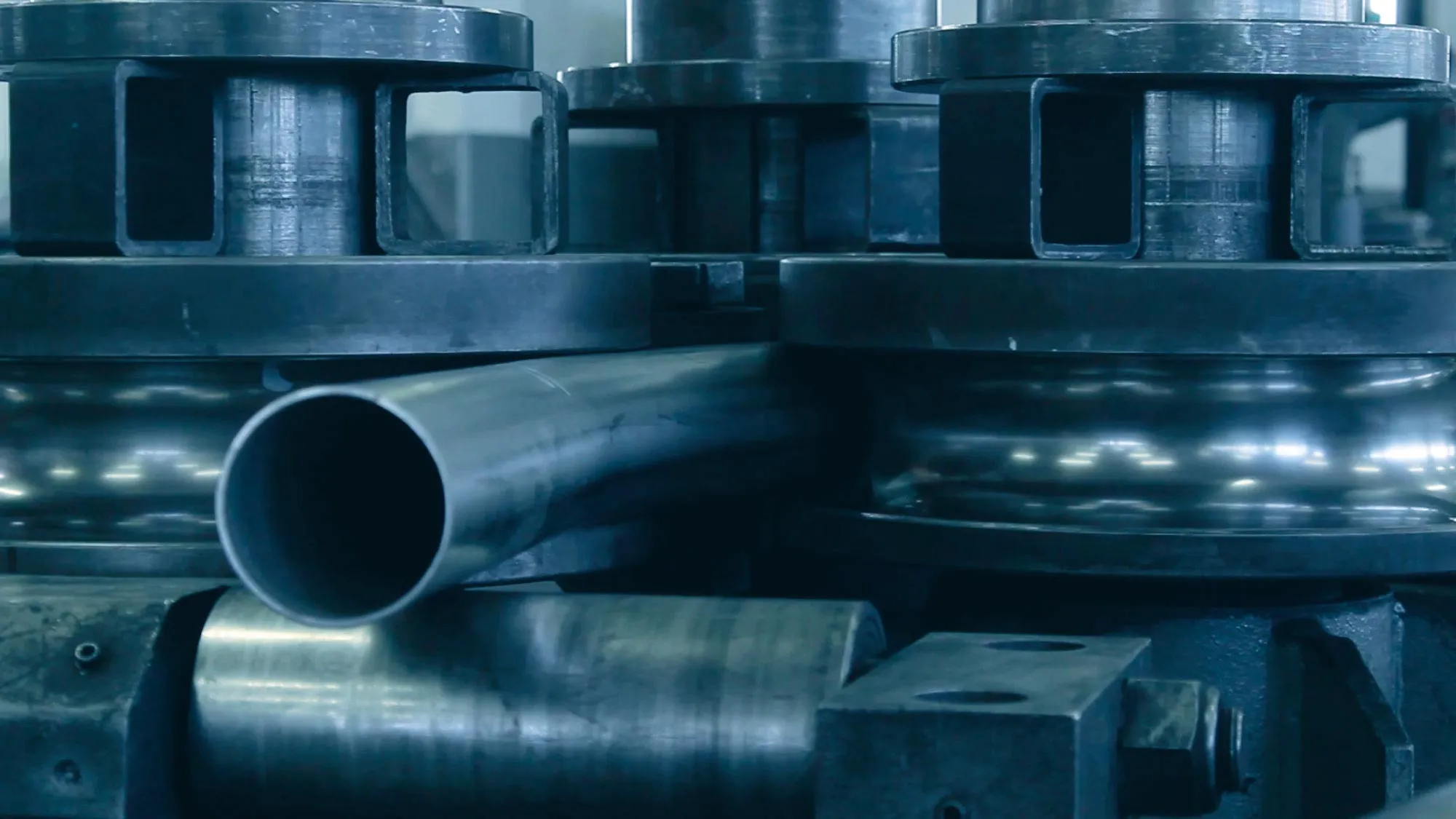

Roll bending is a process of cold deformation of metal tubes, which enables us to obtain a wider bend radius than with CNC bending. In fact, the minimum average roll bending radius is, theoretically, five times the value of the diameter of the tube processed. Roll bending is done with machines called roll benders or section bar benders.

The steel tube is passed through a set of three rollers that, after one or more passages (depending on the difficulty of bending), form an arc with the bend radius required.

Bending and roll bending

Roll bending and laser cutting

Roll bending and milling

Sectors of application: industrial uses

Our roll bent metal tubes in iron, steel and aluminum are used in many industrial sectors.

Tecnocurve has devoted particular attention, over the years, to the roll bending of special custom section bars to drawings, supporting our clients from the initial tests of the design of the metal section bar. A thorough feasibility study by our experts will allow the client to determine the limits and make the alterations necessary to make the section bar usable on the roll bending machinery.

The processing methods we apply to metal tubes

Laser tube and pipe cutting

Thanks to our two modern laser tubes we are able to produce tapered, square and hexagonal holes, slots, tube-end facing, mitre cuts and marking

Tube bending, pipe bending, section bending

With over 30 years’ experience in bending tubes, pipes, sections and tubulars in stainless steel, aluminum and iron, we are one of the few

Tube milling

With our two work centers, here at Tecnocurve we are able to satisfy our clients even with those additional processes that require extreme precision

Lathing metal tubes

Lathing on tubes and solid round bars that can be bent or become parts of welded assemblies. Types of tubes and relative cross sections

Pipe and tube welding

We perform MIG-MAG and TIG welding of tubes, section bars and tubular elements in steel and stainless steel, employing qualified personnel in accordance with

Accessory processing

Accessory processing of tubes, section bars and tubular elements in metal Bent or roll bent metal tubes, section bars and tubular elements can also