Sectors

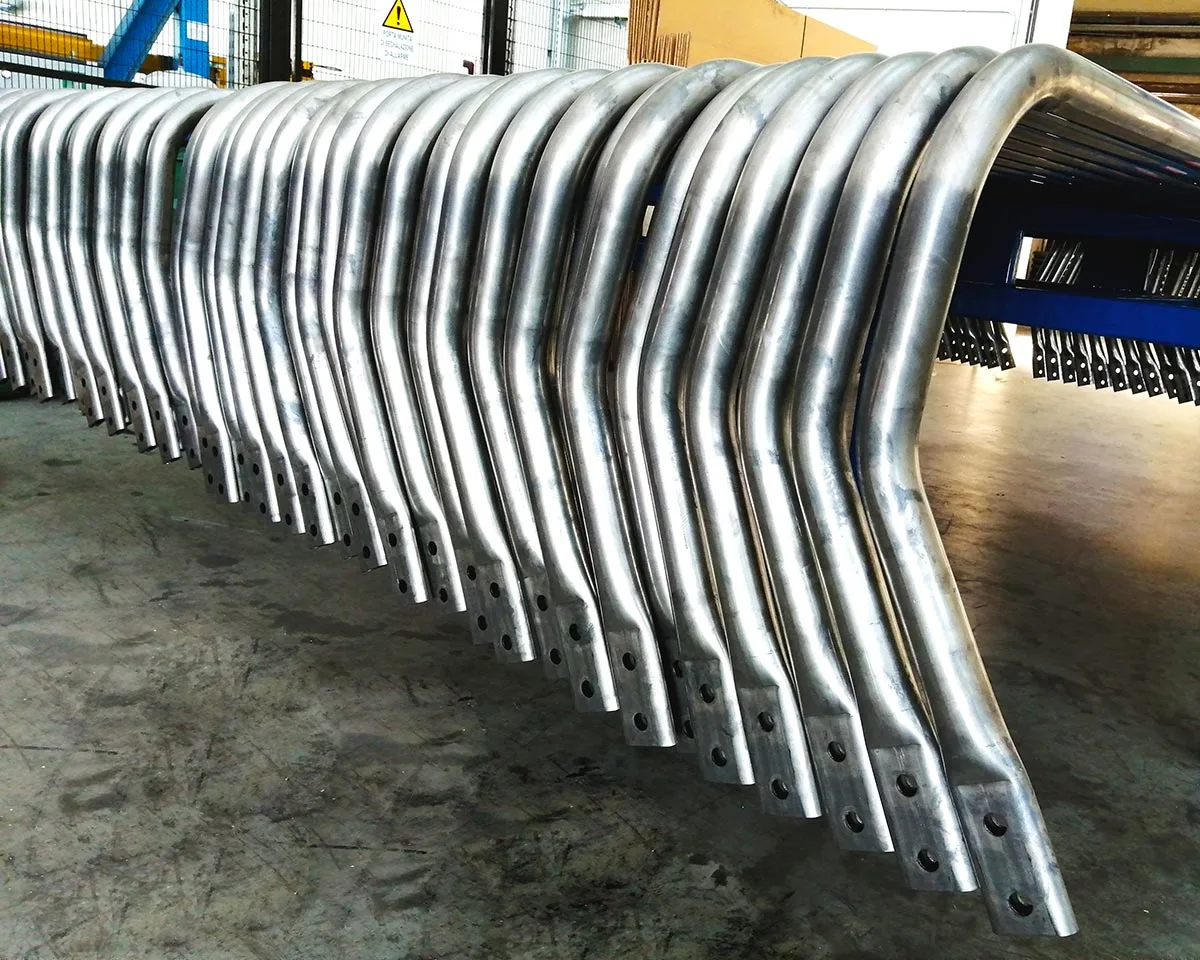

Bending tubes for ski lifts

Professional bending service for tubes, section bars and tubular elements for ski lifts with laser or mechanical marking.

Intended use of bent tubes

The systems used by ski resorts are a sector that requires exceptional attention and precision: when a system is responsible for carrying people safely, security plays a fundamental role and the esthetic element, considering that the installation is always in sight, is also important.

The products constructed with our bent tubes in the ski lift sector include:

- Chairlift structures

- Funicular railway structures

- Ski lifts

- Safety railings

- Structures for attaching ropes

- Chairlifts

- Cable cars

- Telphers

- Monorails

- Tilted elevators

Our certifications

A certified quality management system is essential to guarantee and maintain the company’s performance and value for our clients over the long term.

Tecnocurve is ISO 9001 quality certified by CSQ and since 2020 its production processes have been validated in accordance with UNI EN 1090.

Types of tubes and cross sections

Round metal tubes, square and rectangular tubular elements and section bars are used in ski lift systems. For the structural parts which require excellent strength to ensure the safety of the people transported, steel is fundamental.

Metal alloys

This is a multifaceted sector and for this reason it requires the use of all metals that we at Tecnocurve know well:

Steel

Because of need for particular strength of structural parts in order to guarantee the safety of the people transported, steel is a fundamental material in this sector.

Stainless steel

This is the perfect solution for design elements like handrails or the interiors of cabins or ski lift stations. Stainless steel is elegant and adds esthetic appeal to the details that the user sees.

Aluminum

This is chosen mainly when it is important to reduce the weight of the finished product, or if the mechanical strength of the bent part is not important. A typical example are the armrests of the chairlifts.

Bending methods

Laser cutting and bending

During the initial stage of laser cutting, it is possible to perform all the processes that are easier before bending. These include applying identifying markings in accordance with the customer’s specifications.

Bending and milling

When laser cutting prior to bending cannot ensure the narrow tolerances imposed by certain parts typical of the sector, milling becomes fundamental to guarantee the necessary precision in a view of safety.

Sectors of application: industrial uses

We can offer concrete support for any sector with our work centers.