Sectors

Bending tubes, pipes, section bars and tubular elements for metal carpentry

We perform bending and roll bending processes via CNC, as well as laser cutting and milling on tubes and section bars for products of light and heavy carpentry.

Uses of bent tubes

The use of tubes that have been bent by means of a cold deformation process in the sector of metal carpentry eliminates the need to use other systems of joining, in favor of an esthetically superior product that is also stronger and quicker to produce.

In a sector like this, where the items are usually custom made because they are required for unique projects, our services are fundamental and strategic.

Embracing a number of industrial sectors, the products developed for the carpentry sector are among the most varied that we can find:

- Machinery parts in general

- Guards

- Parts for urban decor

- Roofing

- Bumpers in tubular elements

- Parts for construction work in general

- Shipbuilding

Our certifications

A certified quality management system is essential to guarantee and maintain the company’s performance and value for our clients over the long term.

Tecnocurve is ISO 9001 quality certified by CSQ and since 2020 its production processes have been validated in accordance with UNI EN 1090.

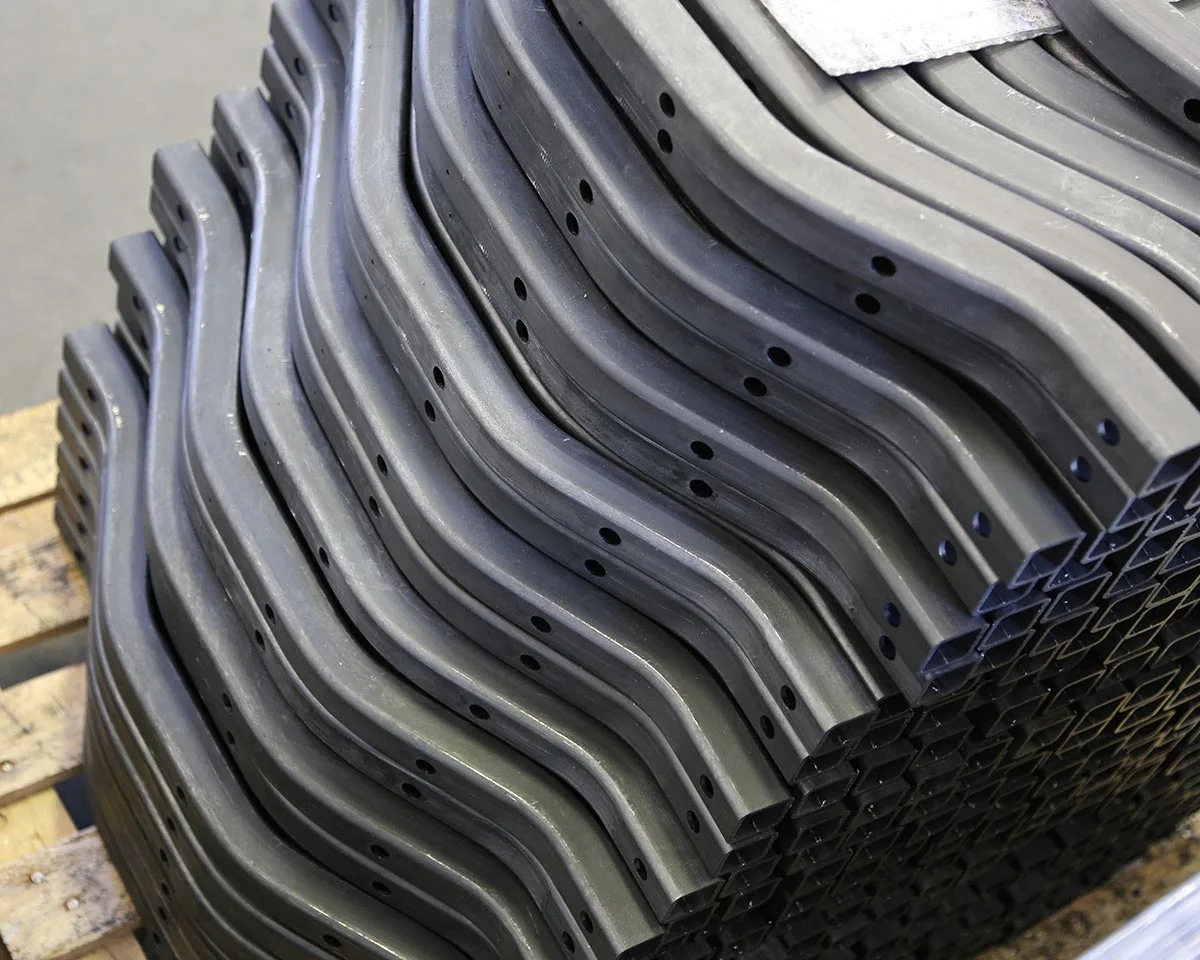

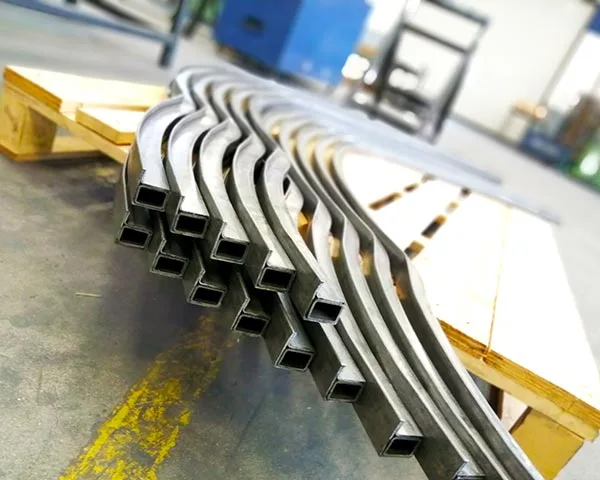

Types of tubes and cross sections

For the carpentry sector we bend and roll bend mainly round tubes, square and rectangular tubular elements and section bars.

Metal alloys processed

For the carpentry sector we bend and roll bend mainly round tubes, square and rectangular tubular elements and section bars.

Steel

Steel is the metal most widely used in this sector as, often, after bending, it needs a welding process that will be less of a problem on steel than on other alloys. In a sector in which strength is considered more important than the esthetic aspect, since we are dealing with structural parts, steel is the answer.

Stainless steel

This is used mainly for those types of carpentry used in the furniture and shipbuilding sectors, as these environments place particular emphasis on the esthetic aspect.

Tube bending methods

Bending and roll bending

A number of different geometries can be achieved by combining these two processes. The choice to use them is made during the initial project study.

Laser cutting and bending

A combination that serves to greatly accelerate the production process; most of the processing can be done on the straight bar.

Bending and milling

When the processes required cannot be done with the laser tube, the work centers take over and can handle the heavier tasks.

Sectors of application: industrial uses

We can offer concrete support for any sector with our work centers.