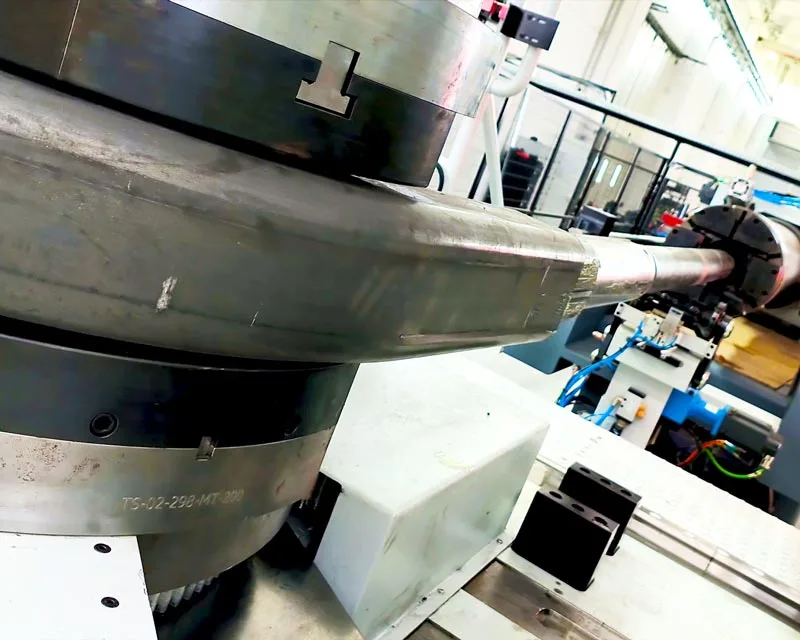

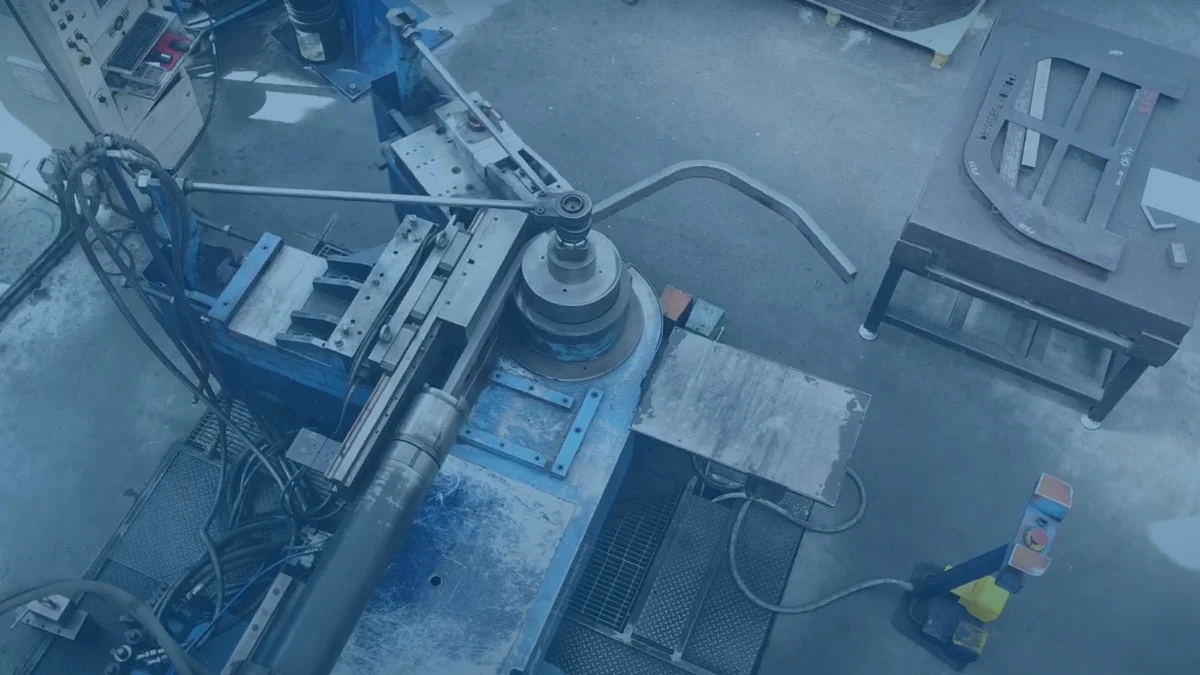

Bending, roll bending and processing of tubes and section bars in metal

Our certifications

A certified quality management system is essential to guarantee and maintain the company’s performance and value for our clients over the long term.

Tecnocurve is ISO 9001 quality certified by CSQ and since 2020 its production processes have been validated in accordance with UNI EN 1090.

A qualified partner

With the support of the advanced technology provided by our machinery, capable of bending cross sections up to Ø219 mm, and spurred by our desire for constant improvement, Tecnocurve offers its clientele a serious partnership, working alongside the client from the design stage through after-sales services with the dedication and quality of skilled workmanship unfailingly performed.

Every person who works at Tecnocurve knows that the client has to be able to rely on a targeted professional collaboration that aims for the maximum satisfaction of the needs expressed, in an atmosphere of trust, serenity and competence.

Steel

Stainless steel

Our tube processing methods

For more information

Everything you want to know about Tecnocurve and its processes.

We will be glad to go into detail with you about bending, roll bending and all the processes we do on tubes in our specialized departments.