Bending pipes and tubes in aluminum

Processing aluminum pipes, tubes and section bars

Light weight and resistance to corrosion are the primary considerations in choosing this metal for any project. On the negative side, however, the aluminum tubes available on the market have the characteristic of having very low elongation percentage, and this makes them difficult to process.

For this reason, tubes, tubular elements and section bars in aluminum can only be processed via cold bending if they are made in specific aluminum alloys that have a certain thermal status, which is a fundamental characteristic on the basis of which the average bend radius of the aluminum tube is defined.

Inspections

very section bar or tube in aluminum delivered to Tecnocurve is subject to strict dimensional, quality and esthetic controls to ensure that the material is suitable for subsequent cold bending.

Quality Certification

It is possible to know the characteristics that make the aluminum compliant with the standards, on the basis of the conformity certificate supplied with it by the manufacturer.

Types of tubes in aluminum and their relative cross sections

Round aluminum tubes

- Minimum cross section: Ø6 mm

- Maximum cross section: Ø219 mm

Square aluminum tube

- Minimum cross section: 10x10 mm

- Maximum cross section:180x180 mm

Rectangular tubular elements

- Minimum cross section: 20x10 mm

- Maximum cross section: 150x100 mm

Section bars

- To determine the feasibility of bending or roll bending a special section bar, a feasibility study is necessary on the specific item.

Methods of bending and processing aluminum tubes

Bending

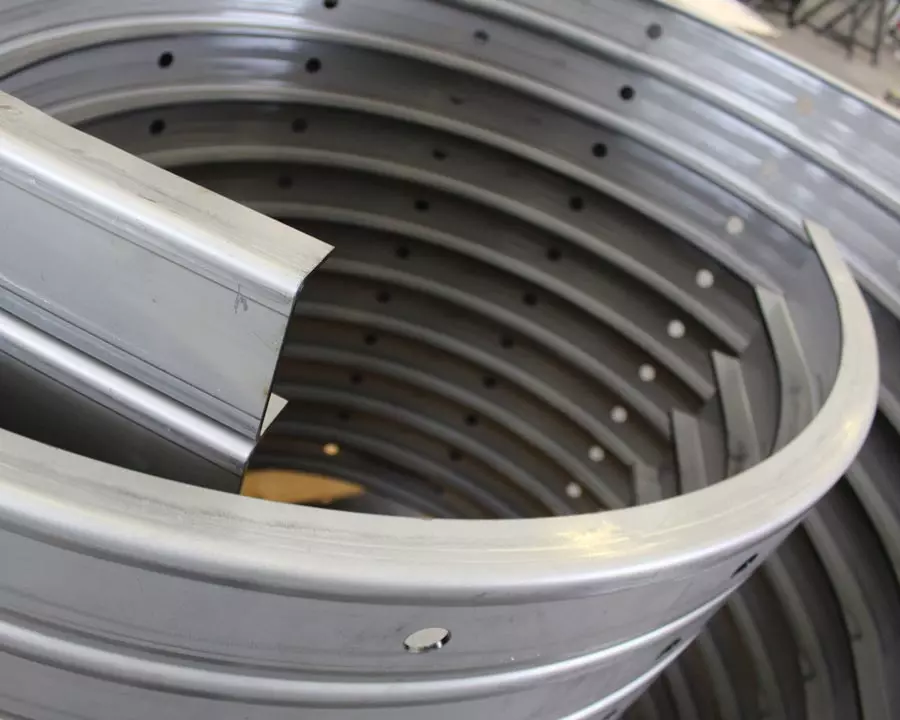

Roll bending

Roll bending is the ideal method for processing this metal as, with its wider radius, it is generally preferable.

On special open section bars, we use specific equipment to limit the deformation.

Laser cutting

Industrial sectors that use bent aluminum section bars and tubes

The bent tube in aluminum is used in many industrial sectors and is a favored material above all because of its light weight and corrosion resistance.

Examples of industrial products made with tubular elements and section bars in bent aluminum are car windows, door handles and railings on boats, light fixtures, etc.

Discover the industrial sectors in which our metal section bars in aluminum are used.

Other metals we process

Stainless steel

Among the special features that recommend the choice of stainless steel, its corrosion resistance is the most important one.

In addition, a significant factor is the esthetic aspect, which is very important in many sectors of use.