Read this article to find out more about tubing bending for agricultural machinery, its function and the importance.

What is agricultural machinery?

The agricultural machine par excellence is undoubtedly the tractor. The various types of agricultural machinery are used as agricultural tools to carry out certain agricultural activities, such as:

Working with soil

Maintenance of green spaces

Sowing seeds

Applying fertiliser

Cultivating and harvesting crops

Haymaking

Tractors are designed so that various implements can be attached to the front or rear, so as to carry out the above agricultural activities. Closed square or rectangular tubes are used instead of open sections.

Bent steel sections are mainly used in the manufacture of cabs.

What types of agricultural machinery are there?

In addition to tractors, there are various types of farm machinery designed for different farming tasks. These machines are manufactured in different sizes to meet the needs of large- and small-scale farming.

The most common types are:

Flail mower

Field sprayer

Seeder

Inter-row mower

Lawn mower

Bale wrapper

Bale gripper

Brush hog

Cultivator

Plough

Bent tubes and sections in agricultural machinery

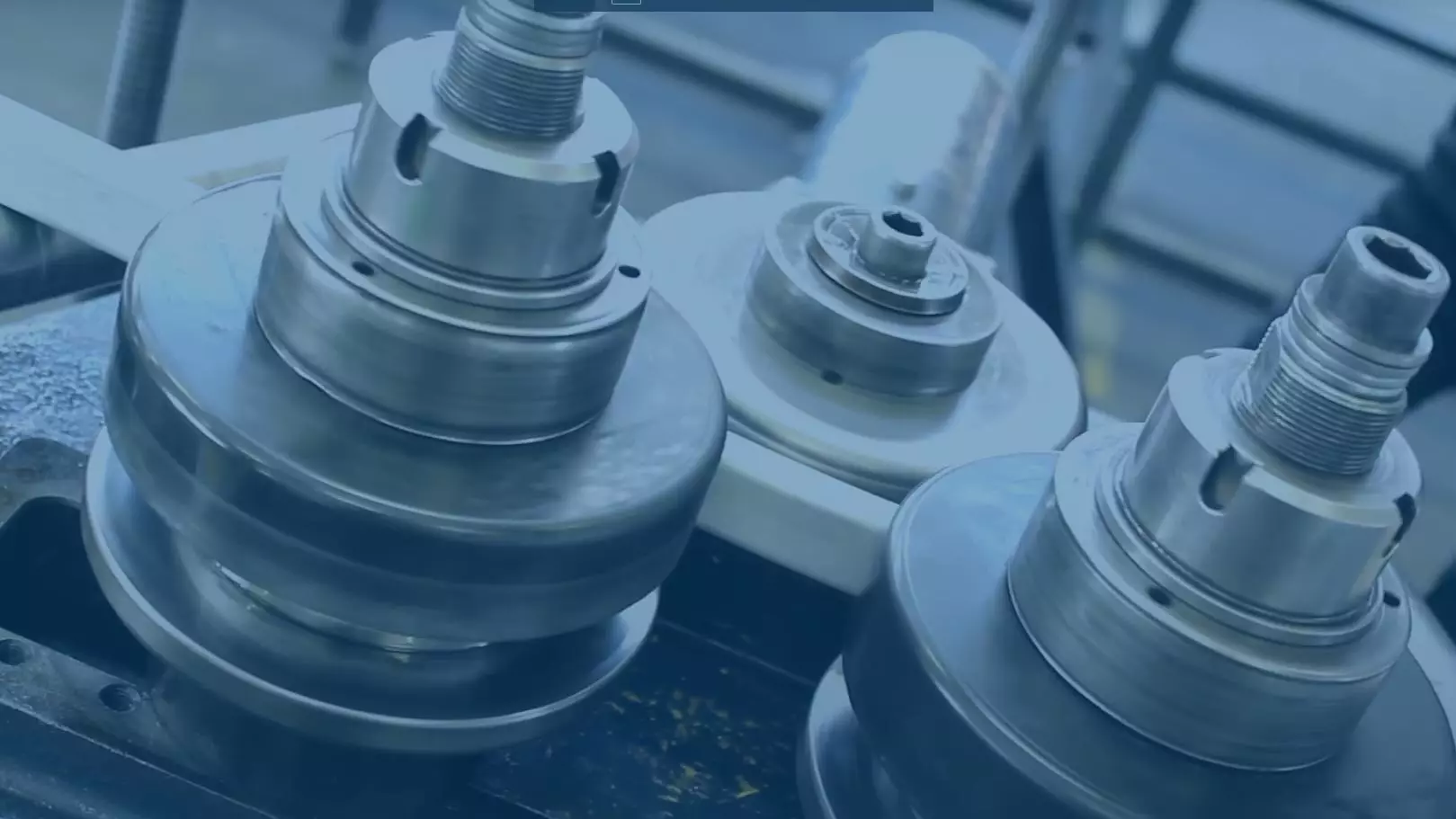

CNC tube bending machines with cold forming are used to produce the bent steel tubes and sections required for the construction of these machines.

The most commonly used tube profiles are square and rectangular, although round tubes are sometimes preferred for design reasons.

Learn the difference between tubes, box section tubes and sections.

The bent and machined tubes and sections are used to make various components, such as:

-

Tractor (three-point) hitches

-

Rollover Protection Structures (ROPS)

-

Hydraulic tubing

-

Frames

The dimensions of the tubes to be bent can vary depending on the requirements of the agricultural machine.

Flail mower by Berti Macchine Agricole

Where the terrain is rougher and the machines are therefore subjected to greater stress, designers in engineering departments choose extra-strong tubes for their agricultural machines, with tube cross-sections of approximately 80 x 80 mm to 160 x 160 mm and tube thicknesses of 6 mm to 12.5 mm.

In contrast, structural tubes are generally smaller, up to 40 × 40 mm, if the agricultural machine will be subject to less stress, as with a lawn mower, for example.

Round tubes are used much less often than rectangular or square tubes.

Why are steel tubes used instead of stainless steel tubes?

As mentioned above, the bending of steel tubes, especially square tubes, is essential for manufacturing agricultural machinery. There are two main reasons for using steel rather than stainless steel to make these tubes:

Steel tubes are less expensive than stainless steel tubes

Steel tubes are easier to work with, as they are easier to cold bend than stainless steel tubes

More about the characteristics of steel pipe bending, and differences between steel and stainless steel bending

Why not use aluminium tubes?

Aluminium is not a suitable metal for manufacturing tubing for these machines, as its low fracture elongation and low weight do not meet the bending requirements for tubing in agricultural machinery.

How are agricultural tubes bent?

The most important form of processing for the bent steel tubes used in the manufacture of agricultural machinery is precision tube bending, which is carried out on specialised tube bending machines.

Tube roll bending, however, is a process used only for the production of a few agricultural machines, such as the harrow tines used as components in cultivators and rotary harrows.

The bending equipment required to bend tubes for agricultural machinery consists of:

A die that determines the bending radius of the tube profile (fixed radius)

A mandrel to limit the deformation in the bent area of the tube

However, depending on the calculation of the feasibility of the tubing bending or the specific geometric shape required by the customer, other tube bending techniques can be used, such as:

Bending with a ball mandrel

Bending with a ball mandrel and wiper die

Combined bending with tube expanders

Variable radius bending

The following video shows the bending of an iron tube used to make a hitch for a flail mower for agricultural and forestry machinery.

Further processing of tube components

In addition to tubing bending and tube expanding machines, we also have a range of machinery that enables us to carry out additional tube machining of the connecting parts. This enables us to guarantee our customers a high standard of quality and the delivery of a bent tube with all the necessary finishes ready for installation.

Laser cutting of tubes is undoubtedly the most important process here, as it not only allows the tube to be cut quickly and accurately, but also allows different types of holes to be drilled into the tube:

Countersunk holes

Slots

Bevelled cuts

However, it is not always possible to process the tube with the laser before bending: If the holes are close to the bending area, the tube must be drilled after bending. This can be done using a CNC milling machine or, alternatively, a semi-automatic drilling centre. The reason for this is the deformation of the tube caused by the holes during bending, which makes the tube unusable.

Another tube machining process that is very important in the agricultural machinery industry is tube welding, which in this particular field is mostly used to join the bent tube to special parts, such as plates or bushings, that are required to manufacture the tube.

Conclusion

The importance of agricultural machinery becomes clear when we consider the importance of agriculture to humankind. Agriculture is one of humanity’s oldest activities, and is essential for food and therefore human survival.

The first rudimentary agricultural machines were built more than 10,000 years ago.

Agricultural machinery allowed humans to transition from nomadic hunter-gatherer lifestyles to permanent settlements, optimising agricultural production and making it more efficient.

Today, Tecnocurve, a company specialising in the bending and rolling of steel tubes and sections, is also contributing to the development of the agricultural supply chain, supplying some of the world’s leading agricultural machinery manufacturers with bent steel sections and tubes for use in the production of modern agricultural machinery.